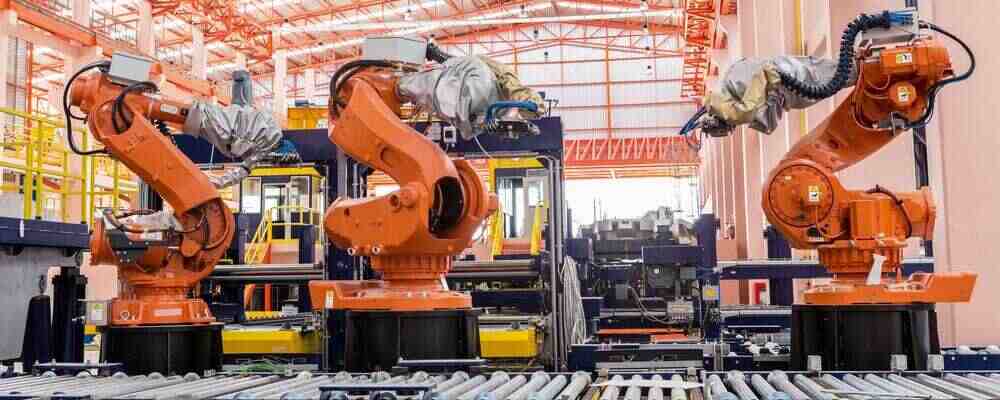

Fault detection in mechanical systems

Utilizing powerful AI technology for fault detection in mechanical systems offers numerous benefits and has the potential to revolutionize maintenance practices. By deploying advanced machine learning algorithms, such as deep learning models, AI can analyze vast amounts of data from sensors and other sources to identify abnormalities and predict potential failures with high accuracy.

This proactive approach enables maintenance teams to address issues before they escalate, leading to minimized downtime, increased operational efficiency, and cost savings in the long run. The implementation of AI for fault detection in mechanical systems facilitates real-time monitoring and continuous analysis of equipment health and performance. This capability allows for early detection of anomalies, trends, or patterns that may indicate impending faults or failures.

By leveraging AI-driven predictive maintenance solutions, organizations can shift from reactive to proactive maintenance strategies, optimizing asset reliability and improving overall maintenance planning and resource allocation. Furthermore, the integration of powerful AI technology into fault detection processes can enable data-driven decision-making and facilitate continuous learning.

AI systems can adapt and improve over time by processing new data inputs and refining their fault detection algorithms based on feedback and performance metrics. This iterative process fosters continuous improvement in fault detection accuracy and reliability, enhancing the effectiveness of maintenance operations and ensuring the longevity of mechanical systems.

Why Data and AI are Essential for Fault Detection in Mechanical Systems?

Data and AI play a crucial role in fault detection in mechanical systems due to their ability to process vast amounts of information and identify intricate patterns that may indicate potential issues. By leveraging data collected from sensors, historical records, and various sources, AI algorithms can analyze this data in real-time to detect anomalies and deviations from normal operating parameters.

This data-driven approach enables early detection of faults that may go unnoticed through traditional methods, enhancing the overall reliability and safety of mechanical systems. Moreover, AI’s capability to continuously learn and improve makes it particularly valuable for fault detection in mechanical systems. Machine learning algorithms can adapt to new data inputs and adjust their detection mechanisms based on feedback, improving their accuracy over time.

This iterative learning process allows AI systems to evolve and become more adept at recognizing complex fault patterns, ultimately leading to more reliable and efficient detection mechanisms in mechanical systems. Additionally, the integration of AI into fault detection processes enhances the predictive maintenance capabilities of organizations, enabling them to move from reactive to proactive maintenance strategies.

By leveraging AI-driven predictive analytics, maintenance teams can anticipate potential failures before they occur, schedule maintenance activities efficiently, and optimize resource allocation. This proactive approach minimizes downtime, increases operational efficiency, and ultimately reduces maintenance costs.

AIMPH – Your Partner in your Project

AIMPH (AI-driven Multiphysics Simulation and Optimization) can serve as an invaluable partner in AI-driven fault detection in mechanical systems due to its ability to simulate complex physical interactions and optimize system performance using artificial intelligence techniques.

By combining Multiphysics simulation capabilities with AI-driven algorithms, AIMPH can accurately model the behavior of mechanical systems under various operating conditions, providing valuable insights into system dynamics and potential failure modes.

The use of AIMPH in fault detection allows for the creation of virtual environments where different failure scenarios can be simulated and analyzed in real-time. These simulations can help uncover vulnerabilities and weaknesses in mechanical systems that may not be apparent through physical testing alone.

By integrating AI algorithms into the simulation process, AIMPH can identify early warning signs of impending faults, enabling operators to take preventive measures before serious issues arise. Furthermore, AIMPH’s optimization capabilities can enhance detection by identifying optimal maintenance schedules, system configurations, and operational parameters that can minimize the risk of failures.

By leveraging AI-driven optimization algorithms, AIMPH can help organizations streamline their maintenance practices, improve system reliability, and reduce downtime. This proactive approach to fault detection, combined with the predictive power of Multiphysics simulations, positions AIMPH as a versatile and effective partner in ensuring the integrity and performance of mechanical systems through AI-driven fault detection.

You can share this post kindly if it’s useful for your fiends and collogues.

Predictive modeling of heart disease progression

Heart Disease Progression Heart disease progression refers to the process by which heart disease dev…

Heart Failure’s Predictive Models

Predictive Models for Heart Failure There are several predictive models for heart failure, each with…

Predictive hospital resource allocation in Oman

Predictive Analytics for Hospital Resource Allocation Predictive analytics in healthcare is a p…

Clinical trial research optimization for Oman healthcare

Clinical Trial Research Optimization Clinical Trial Research Optimization involves strategicall…

Cryptocurrencies sentiment analysis with AI

Cryptocurrencies Sentiment Analysis Analysis of cryptocurrency sentiment Artificial intelligence (AI…

Fault detection in mechanical systems with powerful AI

Fault detection in mechanical systems Utilizing powerful AI technology for fault detection in mechan…